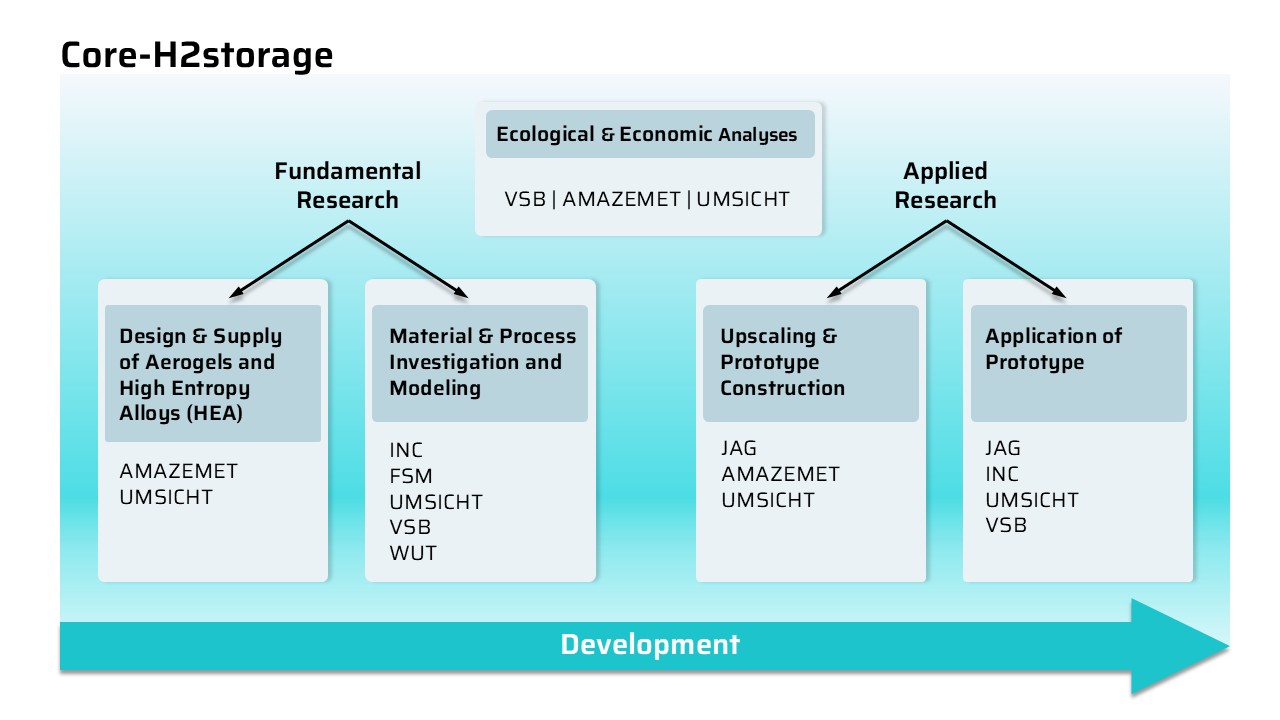

The “Core-H2storage” project aims to make the storage of hydrogen more efficient. Over the course of three years, the project consortium will develop versatile, widely accessible and safe prototypes for low-pressure hydrogen storage tanks. The work of the seven project partners includes basic research into the material properties of hydrogen storage tanks as well as modeling and prototype development and application. The project is divided into eight sub-projects.

Project

Project goals

1. Efficient H2 storage

The efficiency of the storage process was not the main focus of the hydrogen storage processes currently in use. The “Core-H2storage” project is concerned with the cost, resource and energy efficiency of hydrogen storage in order to enable more efficient use of renewable energies.

2. Maximum storage capacity under new conditions

The hydrogen storage capacity is to be maximized by modelling, manufacturing and testing various materials (aerogel/fluid pairs; HEA compositions). The framework conditions to be considered relate to the availability and costs of the materials used on the one hand, and the ecological and economic aspects of the entire storage process on the other. After determining the boundary conditions for possible areas of application, the optimum storage system (Si aerogel or HEA) with the largest possible usable storage capacity can be defined.

3. Safety

Hydrogen storage technologies must be safe. This includes addressing challenges related to storage capacity, leakage prevention, and handling of hydrogen. The sorptive binding of hydrogen in the planned materials fundamentally increases the safety of hydrogen storage. Improving safety is crucial for the widespread acceptance and deployment of hydrogen as an energy carrier.

4. Scalability

The development of scalable hydrogen storage solutions is essential for the commercial viability and widespread adoption of hydrogen technologies.

5. Storage systems in accordance with the legal requirements

For both systems the kinetics of the processes for saturating and releasing hydrogen from the metal volume or the aerogel structure must be taken into account. To be comparable with existing fuel systems the time for refueling should be in the range of three to five minutes.

For hydrogen as a clean energy the quality of hydrogen plays a decisive role. There are quality requirements regarding the use of hydrogen as a fuel such as in PEM fuel cells, that need to be considered for the aerogel and HE-alloy storage systems.

By planning a modular, scalable system, the developed H2-storage systems can be used as buffer storage devices for various applications. This type of storage solution is particularly useful for balancing fluctuations in hydrogen production and demand. Through the further development and optimization of hydrogen buffer storage, we can improve the efficiency and reliability of hydrogen supply and contribute to the development of a more sustainable energy future.